Custom Industrial Robot Programming and Integration Services

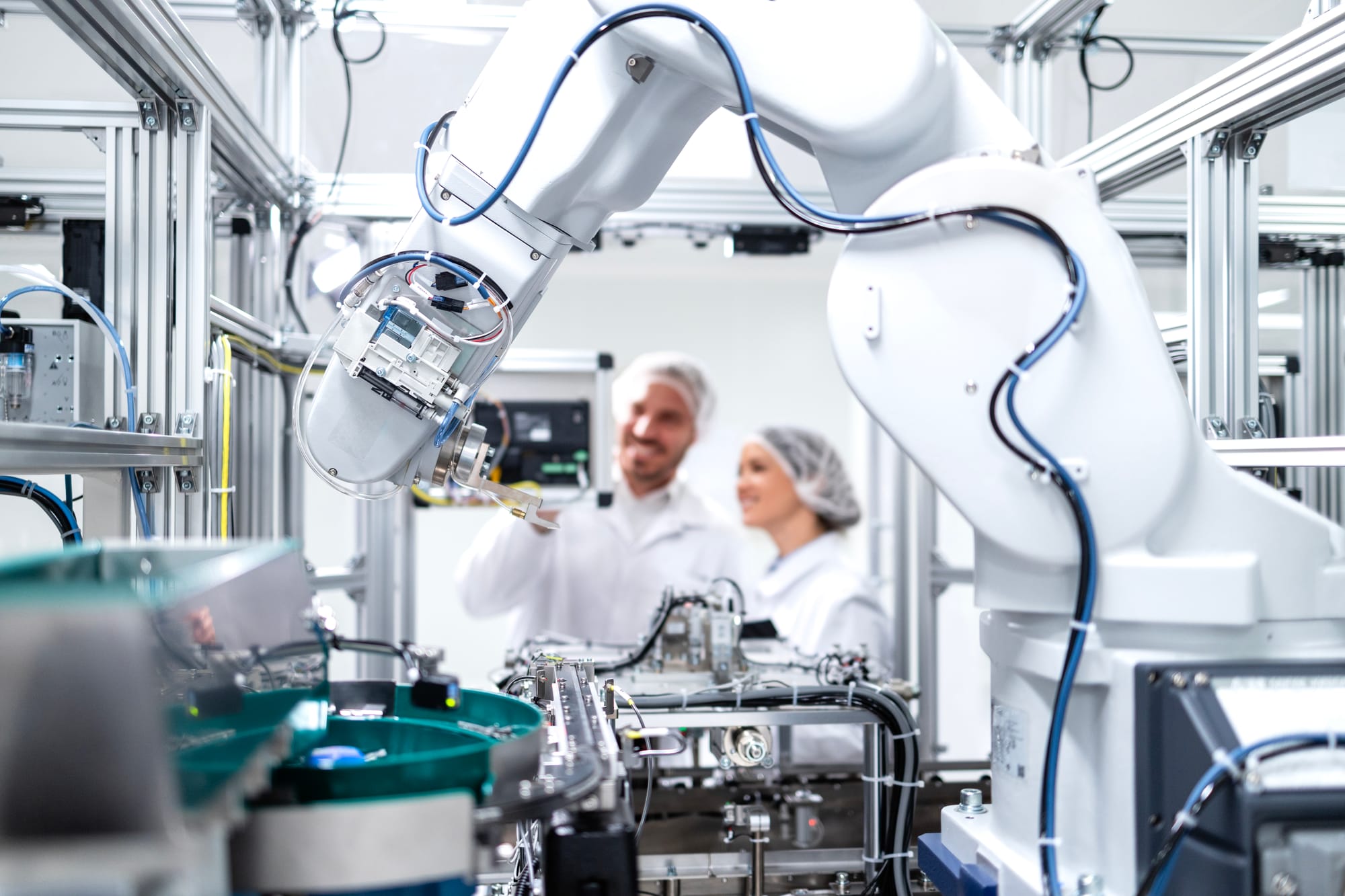

Professional Industrial Robot Programming and Integration Services | Advanced Automation Solutions Maximize your production efficiency with our cutting-edge industrial robot programming and integration services. We provide tailored solutions to meet the demands of modern manufacturing, ensuring precision, reliability, and adaptability for your operations. With years of experience in industrial automation, we offer expertise in optimizing robot performance across diverse applications and industries.

Our Comprehensive Service Portfolio

1. Custom Robot Programming We create custom programs for a wide range of industrial robot models, ensuring seamless integration into your specific production processes. Our programming adapts to unique tasks, enabling robots to perform complex operations with speed and precision.

2. Industrial Process Integration Our team specializes in integrating robots into various industrial workflows, including assembly, welding, material handling, packaging, and inspection. We ensure smooth transitions with minimal downtime, helping your production lines operate at peak efficiency.

3. Program and Motion Optimization We optimize robot programs and movements to minimize cycle times (CT) and increase operational efficiency. By eliminating unnecessary steps and refining motion paths, we help reduce wear and tear while boosting productivity.

4. Simulation and Validation Before implementation, we simulate robotic solutions in virtual environments. This allows us to identify potential issues, test scenarios, and ensure flawless operation in real-world conditions.

5. Gripper System Design and Optimization The performance of a robot heavily depends on its gripping system. We analyze, design, and optimize grippers to ensure precise handling, improved reliability, and adaptability to different products or tasks.

6. Standardized Robot Programming We develop standardized programs for robots, making it easier to diagnose and resolve potential issues during production. This approach ensures consistency and reduces downtime caused by troubleshooting.

7. Smart Camera Integration By incorporating intelligent vision systems, we enable robots to perform complex tasks like quality inspection, object recognition, and adaptive positioning. These systems empower robots to handle variations in real-time.

8. Force Sensor Integration We add force sensors to robotic systems, allowing them to perform delicate operations such as polishing, assembly, and material joining with exceptional precision.

9. Multi-Axis Synchronization Our solutions integrate additional axes into robotic systems, enabling synchronized movements between robots and external axes such as conveyors, turntables, or linear tracks. This enhances flexibility and expands operational capabilities.

10. Adaptive Robotics with Real-Time Feedback Using advanced sensors and smart cameras, we enable robots to adapt dynamically to changing conditions on the production line. This ensures optimal performance even in variable environments.

Key Benefits of Our Services

- Enhanced Productivity: Faster cycle times and efficient robot programming minimize production bottlenecks.

- Improved Reliability: Robust gripping systems and adaptive technologies increase consistency in operations.

- Cost Efficiency: Reduced waste, minimized downtime, and optimized processes save operational costs.

- Scalable Solutions: Whether you need a single robot or an entire automated production line, our solutions grow with your business.

- Future-Ready Automation: Our integration of intelligent systems and adaptive robotics prepares your operations for the demands of Industry 4.0.

Why Choose Us?

At Engineering Hub Solutions , we combine innovation, precision, and experience to deliver automation solutions that transform your manufacturing processes. Our team of specialists works closely with you to understand your goals and design solutions that exceed expectations. With expertise in robot programming, process integration, vision systems, and multi-axis synchronization, we ensure your robots perform seamlessly, reliably, and efficiently.

Let’s Optimize Your Automation Together Invest in smarter automation with our industrial robot programming and integration services. Contact us today to discuss your needs and explore how our solutions can elevate your production capabilities to the next level.